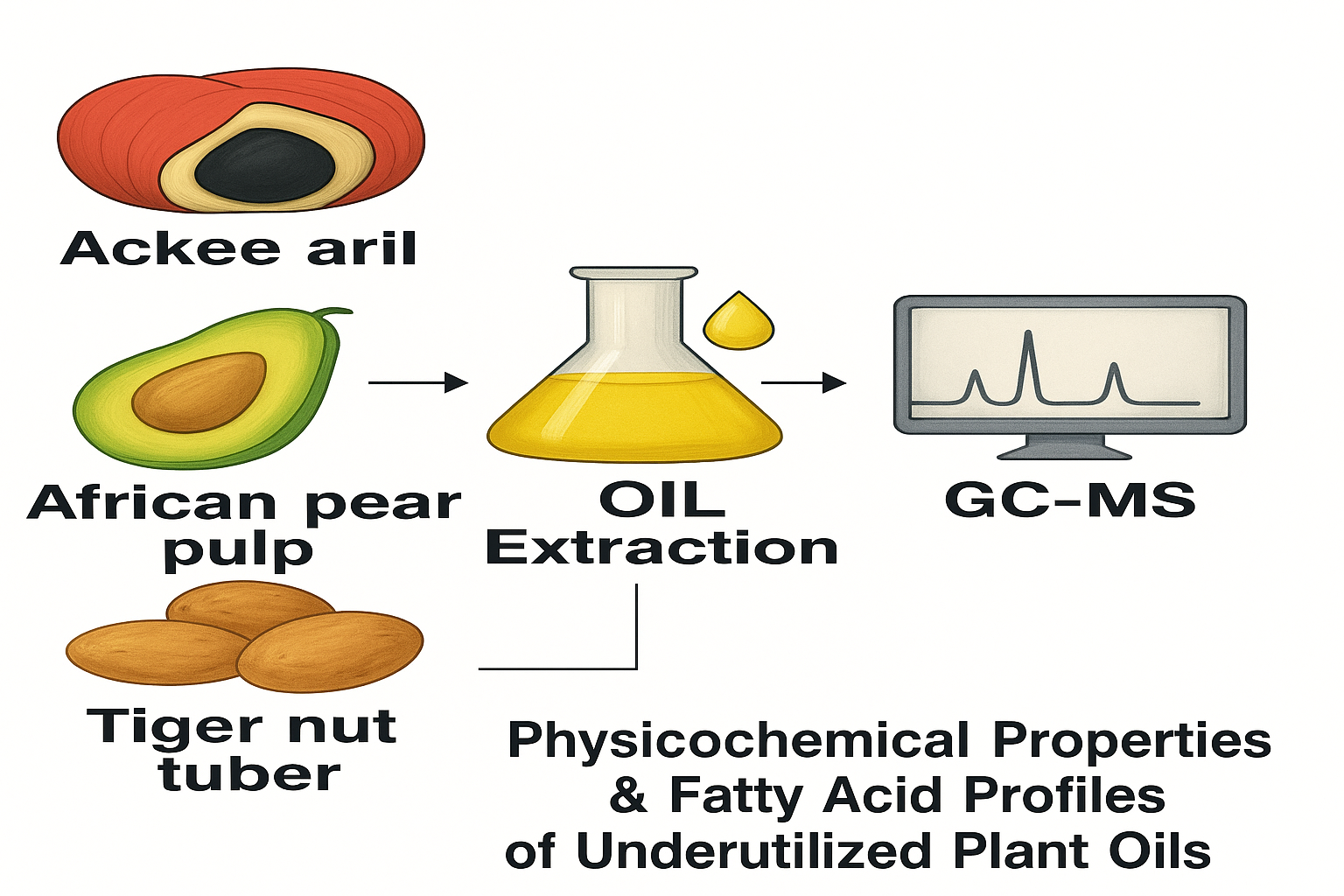

PHYSICOCHEMICAL PROPERTIES AND FATTY ACID PROFILES OF OILS FROM BLIGHIA SAPIDA ARIL, DACRYODES EDULIS PULP, AND CYPERUS ESCULENTUS TUBERS

Main Article Content

Abstract

This study assessed the physicochemical properties and fatty acid composition of oils extracted from Blighia sapida aril, Dacryodes edulis pulp, and Cyperus esculentus tubers to determine their nutritional and industrial potentials using AOAC standard analytical techniques. Oil yields ranged from 18.44% (C. esculentus) to 40.35% (B. sapida). Specific gravities (0.85–0.96 g/cm³) and refractive indices (1.45–1.47) were within Codex standards for edible oils. Acid values varied from 0.92 to 5.02 mg KOH/g, iodine values from 60.24 to 120.54 mg I₂/g, peroxide values from 0.90 to 4.93 mEq/kg, and saponification values from 177.87 to 207.38 mg KOH/g, reflecting differences in quality, stability, and level of unsaturation. Gas Chromatography Mass Spectrometry revealed distinct fatty acid profiles: B. sapida oil was highly saturated (93.46%) dominated by hexadecanoic acid (72.68%) as the major component; D. edulis oil contained a balance of saturated (59.38%) and unsaturated (39.30%) fatty acids, primarily n-hexadecanoic acid (45.60%) and oleic acid (35.26%). Meanwhile C. esculentus oil was rich in unsaturated fatty acids (65.91%), with oleic acid (33.74%) as the most abundant. The findings indicate that B. sapida oil is suitable for thermal and storage stability, D. edulis oil offers nutritional and cosmetic benefits due to its high oleic acid content, and C. esculentus oil has potential applications in both nutrition and biodiesel production. These results highlight the potential nutritional and industrial applications of the oils.

Downloads

Article Details

Section

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.

How to Cite

References

[1] Dhanavel, N., & Nandakrishnan, M.H. (2024). A Review of Animal Fat: A Great Source for Industrial Applications. Journal of Chemical Reviews, 6(2), 115–137. http://doi.org/10.48309/jcr

[2] Zhou, Y., Zhao, W., Lai, Y., Zhang, B., & Zhang, D. (2020). Edible plant oil: Global status, health issues and perspectives. Frontiers in Plant Science, 11(1315), 1–16. http://doi.org/10.3389/fpls.2020.01315

[3] Machado, M., Rodriguez-Alcalá, L. M., Gomes, A. M., & Pintado, M. (2022). Vegetable oils oxidation: mechanisms, consequences and protective strategies. Food Reviews International, 39(7), 4180–4197. http://doi.org/10.1080/87559129.2022.2026378

[4] Tian, M., Bai, Y., Tian, H., & Zhao, X. (2023). The Chemical Composition and Health-Promoting Benefits of Vegetable Oils—A Review. Molecules, 28(17), 6393–6419. http://doi.org/10.3390/molecules28176393

[5] Frydrych, A., Kulita, K., Jurowski, K., & Piekoszewski, W. (2025). Lipids in Clinical Nutrition and Health: Narrative Review and Dietary Recommendations. Foods, 14(3), 473–498. http://doi.org/10.3390/foods14030473

[6] Meijaard, E., Abrams, J. F., Slavin, J. L., & Sheil, D. (2022). Dietary fats, human nutrition and the environment: balance and sustainability. Frontiers in Nutrition, 9, 878644–878651. http://doi.org/10.3389/fnut.2022.878644

[7] Mannucci, P. M., Jolliet, O., Meijaard, E., Slavin, J., Rasetti, M., Aleta, A., & Agostoni, C. (2023). Sustainable nutrition and the case of vegetable oils to match present and future dietary needs. Frontiers in Public Health, 11, 1106083–1106089. http://doi.org/10.3389/fpubh.2023.1106083

[8] Ogunka-Nnoka, C.U., Amadi, P.U., Ogbonna, P.C., & Ogbegbor, P.O. (2017). Assessment of the protein quality and mineral bioavailability of Dacryodes edulis seed and seed coat mixture. Journal of Scientific Research & Reports, 14(1), 1–11. http://doi.org/10.9734/JSRR/2017/32405

[9] Igile, G. O., Ene-Obong, H. N., & Egbung, G. E. (2020). Fatty acids composition, variation and distribution in different accessions of the West African pear (Dacryodes edulis) and potential health benefits. European Journal of Nutrition & Food Safety, 12(5), 35–47. http://doi.org/10.9734/ejnfs/2020/v12i530226

[10] Falloon, O. N., Graham, L., Sadler-McKnight, N., & Goldson-Barnaby, A. (2022). Characterisation, Antioxidant Activity and Chain Breaking Properties of Blighia sapida Oil Extracts. West Indian Journal of Engineering, 44(1), 22–29. http://doi.org/10.47412/AJTD3244

[11] Onuegbu, N. C., Nwuka, M. U., Ojukwu, M. & Kabu, N. O. (2016). Nutritional properties of African pear seed and performance of defatted cake in poultry feed formulations. Journal of Animal Research and Nutrition, 1(2), 1–3. http://doi.org/10.21767/2572-5459.100009

[12] Adepoju, T. F., Esu, I. O., Olu-Arotiowa, O. A., & Blessed, E. (2019). Oil extraction from butter fruit (Dacryodes edulis) seeds and its optimization via response surface and artificial neural network. Nigerian Journal of Technological Development, 16(2), 56–62. https://doi.org/10.4314/njtd.v16i2.2

[13] Wray, D., Goldson-Barnaby, A., & Bailey, D. (2020). Ackee (Blighia Sapida KD Koenig)—a review of its economic importance, bioactive components, associated health benefits and commercial applications. International Journal of Fruit Science, 20(2), 910–924. https://doi.org/10.46592/turkager.1384004

[14] Dagaci, M. Z., Hassan, L. G., Umar, K. J., Paiko, Y. B. & Lakan, I. I. (2015). Physicochemical analysis of Blighia sapida (Sapindaceae) seed oil from Zago, Agaie Local Government Area of Niger State. Jewel Journal of Scientific Research, 3(1), 7–13. https://journals.fukashere.edu.ng/index.php/jjsr

[15] Olabinjo, O.O., & Sama, M.O. (2023). Evaluating the Effects of Drying Temperatures on the Nutritional and Bioactive Quality of Ackee Aril Apples. Turkish Journal of Agricultural Engineering Research (TURKAGER), 4(2), 289–300. https://doi.org/10.46592/turkager.1384004

[16] Olaniyi, O. B., Oluwaniyi, O. O., Oloruntele, O. I., & Sekoni, A. H. (2022). Investigation of physicochemical and fatty acid composition of oils from ripe and unripe Blighia sapida fruit. Advanced Journal of Chemistry, Section B: Natural Products and Medical Chemistry, 4(1), 53–61. https://doi.org/10.22034/ajcb.2022.330991.1110

[17] Lawal, R. T., Oyeleke, G. O., Ishola, A. D., & Akinsuroju, M. O. (2018). Determination of physiochemical properties and lactic acid bacteria presence in ackee (Blighia sapida) fruit. International Journal of Environment, Agriculture and Biotechnology, 3(3), https://doi.org/1079–1082. 10.22161/ijeab/3.3.47

[18] Adel, A. A. M., Awad, A. M., Mohamed, H. H., & Iryna, S. (2015). Chemical composition, physicochemical properties and fatty acid profile of tiger nut (Cyperus esculentus L) seed oil as affected by different preparation methods. International Food Research Journal, 22(5), 1931. https://doi.org/10.1590/01012061cta43.2.12

[19] Adenowo, A. F., & Kazeem, M. I. (2020). Tiger nut as a functional food, pharmacological and industrial agent: a mini review. Annals of Science and Technology, 5(1), 31–38. https://doi.org/10.2478/ast-2020-0004

[20] Asare, P. A., Kpankpari, R., Adu, M. O., Afutu, E., & Adewumi, A. S. (2020). Phenotypic characterization of tiger nuts (Cyperus esculentus L.) from major growing areas in Ghana. The Scientific World Journal, 1, 1–11. https://doi.org/10.1155/2020/1041916

[21] Yu, Y., Lu, X., Zhang, T., Zhao, C., Guan, S., Pu, Y., & Gao, F. (2022). Tiger Nut (Cyperus esculentus L.): Nutrition, Processing, Function and Applications. Foods (Basel, Switzerland), 11(4), 601–620. https://doi.org/10.3390/foods11040601

[22] Chen, Y., Touboul, R., Chang, C. L., & Collaborators. (2025). Strategic delivery of omega-3 fatty acids for modulating inflammatory neurodegenerative diseases. Frontiers in Aging Neuroscience, 17, 1-19. https://doi.org/10.3389/fnagi.2025.1535094

[23] Islam, F., Imran, A., Nosheen, F., Fatima, M., Arshad, M. U., Afzaal, M., Ijaz, N., Noreen, R., Mehta, S., Biswas, S., Rasool, I. F. U., Aslam, M. A., Usman, I., Zahra, S. M., Segueni, N., & Amer Ali, Y. (2023). Functional roles and novel tools for improving-oxidative stability of polyunsaturated fatty acids: A comprehensive review. Food science & nutrition, 11(6), 2471–2482. https://doi.org/10.1002/fsn3.3272

[24] Abubakar, A., Mahmoud, A.A., Hamza, Y., & Salim, Y. (2020). Extraction and Physicochemical Characterization of Seed Oil from Terminalia mantaly Seed. International Journal of Research and Innovation in Applied Science, 5(1), 60–64. www.rsisinternational.org

[25] Carvalho, A. P., & Malcata, F. X. (2005). Preparation of fatty acid methyl esters for gas-chromatographic analysis of marine lipids: insight studies. Journal of agricultural and food chemistry, 53(13), 5049–5059. https://doi.org/10.1021/jf048788i

[26] Anwar, A., Hyder, S., Sabir, S., Chand, D., & Nain, A. K. (2006). Volumetric, viscometric, and refractive index behaviour of α-amino acids in aqueous glucose solution at different temperatures. Journal of Chemical Thermodynamics, 38(2), 136–143. https://doi.org/10.1016/j.jct.2005.04.011

[27] Mohammadi, A., Jafari, S. M., Esfanjani, A. F., & Akhavan, S. (2016). Application of nano-encapsulated olive leaf extract in controlling the oxidative stability of soybean oil. Food Chemistry, 190, 513–519. https://doi.org/10.1016/j.foodchem.2015.05.113

[28] Gazwi, H. S. S. (2017). Oxidative stability of sunflower oil as affected by Carica papaya leaves extracts during accelerated oxidative storage. International Journal of Biosciences, 11(4), 116–126. http://dx.doi.org/10.12692/ijb/11.4.116-5

[29] Ogbeide, O. K., Omorotionmwan, E. A., Igenumah, O. D., Ifijen, H. I., & Akhigbe, I. U. (2022). Comparative analysis on physicochemical properties and chemical composition of coconut and palm kernel oils. ChemSearch Journal, 13(1), 70–75. http://www.ajol.info/index.php/csj

[30] Chen, C., Mokhtar, R. A. M., Sani, M. S. A., & Noor, N. Q. I. M. (2022). The Effect of Maturity and Extraction Solvents on Bioactive Compounds and Antioxidant Activity of Mulberry (Morus alba) Fruits and Leaves. Molecules (Basel, Switzerland), 27(8), 2406-2426. https://doi.org/10.3390/molecules27082406

[31] Lee, K., Kim, H. J., Kerr, W. L., & Choi, S. G. (2024). Effect of oil pressing and packaging under oxygen-free conditions on yield, oxidative stability and antioxidant activity of perilla oil. Food Science and Technology, 179, 1–8. https://doi.org/10.1016/j.lwt.2023.114647

[32] Codex Alimentarius Commission. (2019). Standard for named vegetable oils (CODEX STAN 210-1999). Rome: FAO/WHO.

[33] Owheruo, J. O., Edo, G. I., Akpoghelie, P. O., Okoronkwo, K. A., Nwaogu, M. U., Ojulari, A. E., & Agbo, J. J. (2024). Physicochemical characteristics of oils extracted from underutilized seeds in Delta State, Nigeria. Natural Resources for Human Health, 4(1), 108–114. https://doi.org/10.53365/nrfhh/176713

[34] Akinyede, A. I., Fagbemi, T. N., Osundahunsi, O. F., & Aluko, R. E. (2016). Physicochemical composition and oil characterization of Dioclea reflexa and Monodora myristica seeds. Applied Tropical Agriculture, 21(3), 1–11. https://appliedtropicalagriculture.com/

[35] Muhammad, H. S., Agada, R., Ogaji, I. J., & Ngwuluka, N. C. (2023). Physicochemical characterization and fatty acids composition of four indigenous plant oils. Scientific African, 20, 1–13. https://doi.org/10.3389/fceng.2024.1451187

[36] Jolayemi, O. S., & Muritala, Y. (2022). Confirmatory assessments of nutritional properties of commercial edible oils. Measurement: Food, 7, 1–7. https://doi.org/10.2139/ssrn.4024908

[37] Negash, Y.A., Amare, D.E., Bitew, B.D. and Dagne, H., 2019. Assessment of quality of edible vegetable oils accessed in Gondar City, Northwest Ethiopia. BMC research notes, 12(1), 793-798. https://doi.org/10.1186/s13104-019-4831-x

[38] Uhunmwangho, E. S., & Omoregie, E. S. (2022). Changes in lipid class and fatty acid composition during the development of African pear (Dacryodes edulis). African Journal of Biochemistry Research, 16(1), 24–31. https://doi.org/10.5897/AJBR2017.0927

[39] Zhang, N., Li, Y., Wen, S., Sun, Y., Chen, J., Gao, Y., & Yu, X. (2021). Analytical methods for determining peroxide value of edible oils: a mini-review. Food Chemistry, 358, 1–8. https://doi.org/10.1016/j.foodchem.2021.129834

[40] Dymińska, L., Calik, M., Albegar, A.M.M., Zając, A., Kostyń, K., Lorenc, J., & Hanuza, J. (2017). Quantitative determination of iodine values of unsaturated plant oils using spectroscopy. International Journal of Food Properties, 20, 2003–2015. https://doi.org/10.1080/10942912.2016.1230744

[41] Ichu, C. B., & Nwakanma, H. O. (2019). Comparative study of the physicochemical characterization and quality of edible vegetable oils. International Journal of Research in Informative Science Application & Techniques (IJRISAT), 3(2), 1–9. https://doi.org/10.46828/ijrisat.v3i2.56

[42] Fortin, N. D. (2023). Global governance of food safety: the role of the FAO, WHO, and Codex Alimentarius. In Research Handbook on International Food Law (pp. 227–242). Edward Elgar Publishing.

[43] Haruna, M., Umar, B.Y., Sharif, N.U., & Hamza, A. (2019). Synthesis, characterization, antimicrobial activity and performance of alkyd resin derived from mahogany seed oil. Nigerian Journal of Pure and Applied Science, 32, 3272–3280. doi: http://dx.doi.org/10.19240/njpas.2019.A01

[44] Symoniuk, E., Wroniak, M., Napiórkowska, K., Brzezińska, R., & Ratusz, K. (2022). Oxidative stability and antioxidant activity of selected cold-pressed oils and oil mixtures. Foods, 11(11), 1597–1616. https://doi.org/10.3390/foods11111597

[45] Ogbuanu, C. C., Chime, C. C., & Nwagu, L. N. (2015). Physiochemical and fatty acid analysis of Virescens (Ojukwu) oil and Nigrescens (ordinary) palm oil of Eleaisguineensis. African Journal of Food Science 9(7), 400-405. https://doi.org/10.5897/AJFS2014.1254

[46] Langa, A.M., Padonou, E.A., Akabassi, G.C., Akakpo, A.B., Idohou, R. and Assogbadjo, A.E. (2022) Physico-Chemical Properties of Crude Oil of Khaya senegalensis (Desr.) A. Juss According to Bioclimatic Zones in Chad. Moroccan Journal of Agricultural Sciences, 3, 203-206. https://doi.org/10.5281/zenodo.8027421

[47] Grande-Tovar, C. D., Johannes, D. O., Puerta, L. F., Rodriguez, G. C., Sacchetti, G., Paparella, A., & Chaves-Lopez, C. (2019). Bioactive micro-constituents of ackee arilli (Blighia sapida). Annals of the Brazilian Academy of Sciences, 91(3), 1–15. http://dx.doi.org/10.1590/0001-3765201920180140

[48] Hewavitharana, G. G., Perera, D. N., Navaratne, S. B., & Wickramasinghe, I. (2020). Extraction methods of fat and preparation of fatty acid methyl esters for gas chromatography: A review. Arabian Journal of Chemistry, 13(11), 6865–6875. https://doi.org/10.1016/j.arabjc.2020.06.039

[49] Oluba, O. M., Mbamara, D. O., Akpor, O. B., Adebiyi, F. D., Alabi, O. O., Shoyombo, A., & Osemwegie, O. O. (2021). Effects of drying methods on compositional and functional characteristics of Blighia sapida aril oil. Oilseeds and Fats Crops and Lipids, 28(17), 1–10. https://doi.org/10.1051/ocl/2020064

[50] Diakaridja, N., Ouehi, D., Fatimata, N., Lacroux, É., Valentin, R., Cerny, M., Mouloungui, Z., & Koua, O. K. (2024). Physicochemical characterization of non-wood forest product oils. Science Journal of Chemistry, 12(6), 124–134. https://doi.org/10.11648/j.sjc.20241206.12

[51] Hoba, A. M. F., Digbeu, Y. D., Binaté, S., Dué, E. A., & Kouamé, L. P. (2018). Fatty acids and physicochemical compositions of dried and roasted Blighia sapida arils oils. Asian Journal of Research in Biochemistry, 2(1), 1–7. https://doi.org/10.9734/AJRB/2018/v2i1374

[52] Aburime, L. C., & Otache, G. O. (2024). Effect of processing methods on fatty acid profile of African pear (Dacryodes edulis). Journal of Home Economics Research, 31(1), 50–58. https://journals.heran.org/index.php/JHER/article/view/487

[53] Amoren, E. L., Iyekowa, O., & Oviawe, A. P. (2022). Fatty acid profile of oils from African pear (Dacryodes edulis) seed and African star apple. Nigerian Journal of Scientific Research, 21(1), 79–84. https://journals.abu.edu.ng/index.php/njsr

[54] Isong, A. U., Davies, A. U., Elechi, O., & Effiong, E. I. (2021). Biodiesel synthesis from African pear (Dacryodes edulis) oil using catalyst-assisted transesterification. World Journal of Applied Chemistry, 5(4), 65–69. https://doi.org/10.11648/j.wjac.20200504.12

[55] Uhunmwangho, E. S., & Omoregie, E. S. (2017). Lipid class and fatty acid composition of African pear (Dacryodes edulis). African Journal of Biochemistry Research, 16(1), 24–31. https://doi.org/10.5897/AJBR2017.0927

[56] Jenkins, D. J., Kendall, C. W., & Sievenpiper, J. L. (2021). Plant polyphenols lignans and cardiovascular disease. Journal of the American College of Cardiology, 78(7), 679-682. https://doi.org/10.1016/j.jacc.2021.06.014

[57] Aremu, M. O., Ambo, I. A., Onwuka, J. C., Akpomie, T. M., & Omotehinwa, F. H. (2025). Assessment of fatty acid profile and sugar content of African black pear (Dacryodes edulis). Bangladesh Journal of Scientific and Industrial Research, 60(2), 73–82. https://doi.org/10.3329/bjsir.v60i2.78348

[58] Akusu, O. M., & Wordu, G. O. (2019). Physicochemical properties and fatty acid profile of Allanblackia seed oil and African pear pulp oils. International Journal of Biotechnology and Food Science, 7(2), 14-22. https://doi.org/10.33495/ijbfs_v7i2.19.102

[59] Aljuhaimi, F., Ghafoor, K., Özcan, M. M., Miseckaite, O., Babiker, E. E., & Hussain, S. (2018). Effect of solvent type and roasting on properties of tigernut oil. Journal of Oleo Science, 67(7), 823–828. https://doi.org/10.5650/jos.ess17281

[60] Özcan, M. M., & Yılmaz, H. (2024). Comparison of bioactive properties and components of germinated, roasted, and boiled chufa tubers. JSFA Reports, 4(5), 243–254. https://doi.org/10.1002/jsf2.207

[61] Ogbeide, O. K., Jackson-Akpamu, C. O., & Akhidenor, D. O. (2025). Physicochemical analysis and antimicrobial activity of a cream from Cyperus esculentus oil. Mediterranean Journal of Pharmacy and Pharmaceutical Sciences, 5(2), 49–61. https://doi.org/10.5281/zenodo.15225961

[62] Guo, T., Wan, C., Huang, F., & Wei, C. (2021). Evaluation of quality properties and antioxidant activities of tiger nut (Cyperus esculentus L.) oil produced by mechanical expression or/with critical fluid extraction. LWT - Food Science and Technology, 141, 1-7. https://doi.org/10.1016/j.lwt.2021.110915

[63] Li, Z. C., Zhang, Z. S., Xia, Y., Han, J. T., Chang, H. Z., & Wang, H. M. (2025). Extraction of tiger nut oil using ultrasound-assisted immiscible binary solvents and its effect on quality of extracted oil and starch. Ultrasonics Sonochemistry, 112, 107191. https://doi.org/10.1016/j.ultsonch.2024.107191

[64] Slobodianiuk, L., Budniak, L., Marchyshyn, S., & Ivasiuk, I. (2021). Fatty Acids Composition Study of Cyperus esculentus L. Norwegian Journal of Development of the International Science, (53-1), 20-23. https://nor-ijournal.com/

[65] Ezeh, O., Gordon, M. H., & Niranjan, K. (2016). Enhancing the recovery of tiger nut (Cyperus esculentus) oil by mechanical pressing: Moisture content, particle size, high pressure and enzymatic pre-treatment effects. Food Chemistry, 194, 354-361. https://doi.org/10.1002/ejlt.201300446

[66] Zhang, Y., & Sun, S. (2023). Tiger nut (Cyperus esculentus L.) oil: A review of bioactive compounds, extraction technologies, potential hazards and applications. Food Chemistry: 19, 1-16. https://doi.org/10.1016/j.fochx.2023.100868

[67] Nawaz, K., Nisar, J., Anwar, F., Waseem Mumtaz, M., Ali, G., Ur Rehman, N., & Ullah, R. (2023). Optimised transesterification of used frying oils: production and characterisation of biodiesel. International Journal of Environmental Analytical Chemistry, 103(7), 1615-1632. https://doi.org/10.1080/03067319.2021.1878164